Services

Resources

Get in Touch

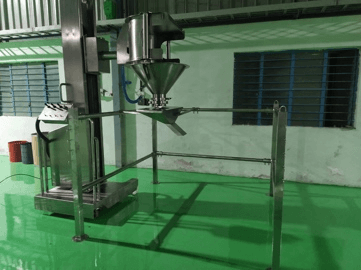

Automed solutions are custom designed to solve process problems.

Based on a detailed need analysis, we design and build lifting solutions to meet your lifting and placing requirements, Drum inverting and docking systems.

We build GMP compliant systems suitable for use in Clean areas and designed for washdown cleaning methods.

Be it to invert your 50Kg bins or lift your heavy 300kg IBC bins, we have a solution to meet your standards.

We offer this in various configurations to meet our customer needs