Services

Resources

Get in Touch

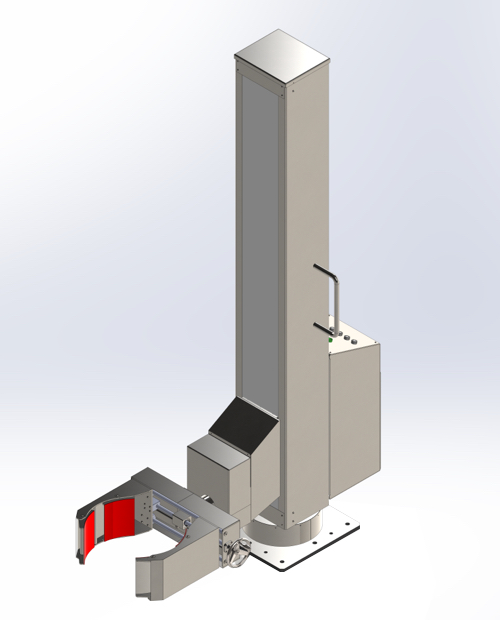

Automed Designed lifting and positioning device is an versatile systems which can be used for handling of drums, containers, Intermediate Bulk Containers (IBCs/Bins), and small machines like mills, pneumatic conveyors, and calibrators.

The Automed LPD is an automated lifting system for heavy loads (containers) and can Lift, Invert, controlled lowering and Dock with precision with automated valves or process equipment ; ensuring safe, accurate and repeatable process.

Our control systems are intuitive and has been designed for minimal intervention of the operator, programmed functions can execute specified sequences with precision.

Automed designs lifting mechanism to suit customer application, which can be a screw thread or a pulley based systems. It can be powered by electrical unit with a motor / gearbox arrangement. Or it can be completely powered by hydraulic or pneumatic systems.

LPD comes with all safety interlocks, and is build to be a fail safe device to prevent any unsecured slipping.

The unit can be a mobile unit or a floor mounted unit and with a slewing ring, 350 degree base rotation is possible, to enable picking up load from one side and discharge on the other side.

The simple design and the accurate finishing allows easy cleaning operations.

Different holding systems can be fitted on the lifting arm to hold IBCs, drums, special containers or other machines.